Process Engineering Industrial Placement

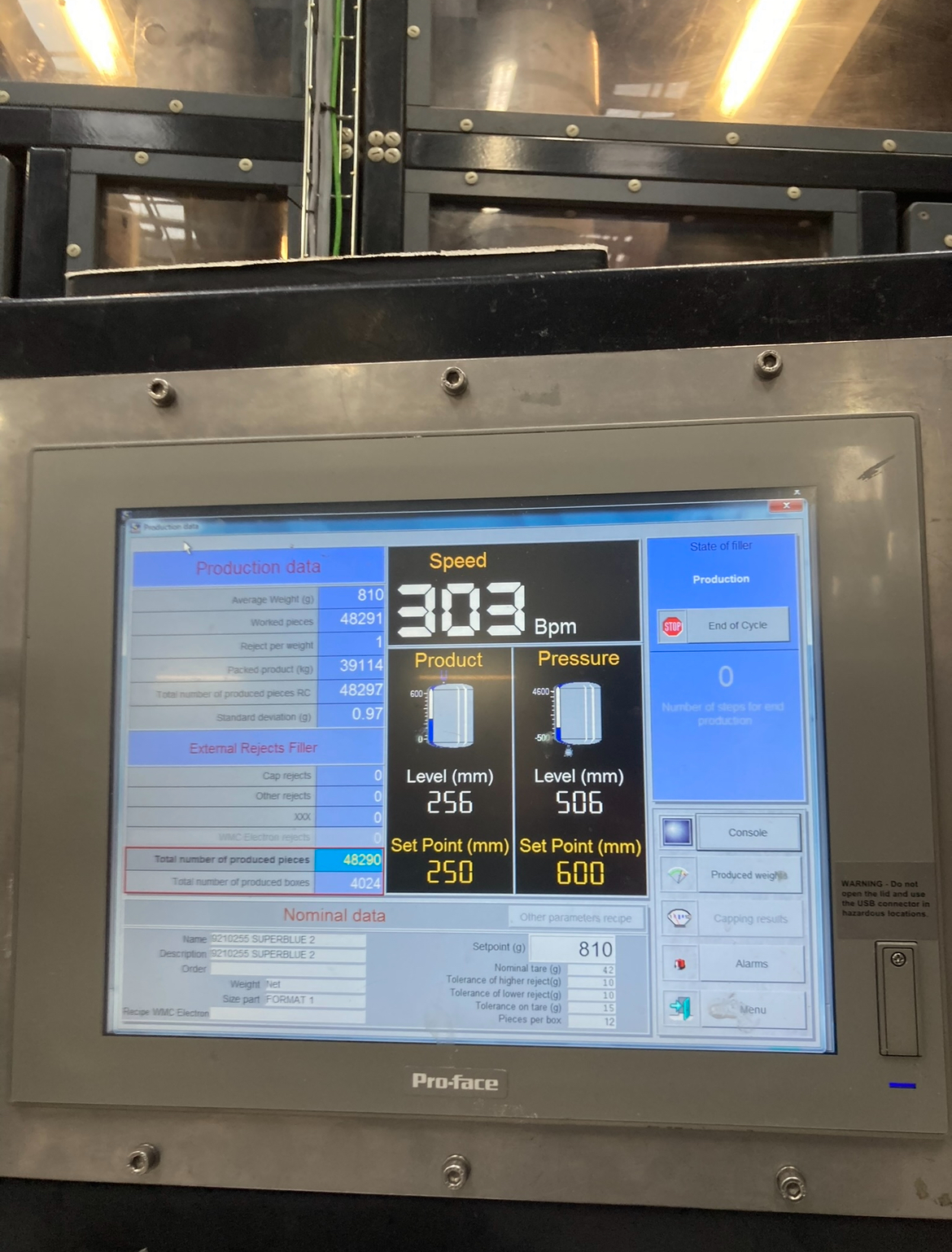

During my year in industry I worked on a production line:

- Focused on improving the efficiency of a production line by developing innovative solutions...

- Reduced downtime from 5.09% to 2.28% within one month, leading to +216,000 bottles and saving 315kg of plastic waste.

- Standardised procedures through creating documentation and training operators.

- Advanced waste reduction initiatives, including lowering water usage in wash cycles.

- Designed and manufactured a reject system for incorrectly orientated bottles.

- Daily Excel data analysis to identify improvements and inform decisions.

- Optimised machinery for packaging a new product.

- Developed a Power Apps digital application for production data recording.

- Created a Python web scraping script to extract data automatically.